Going Beyond the Standard

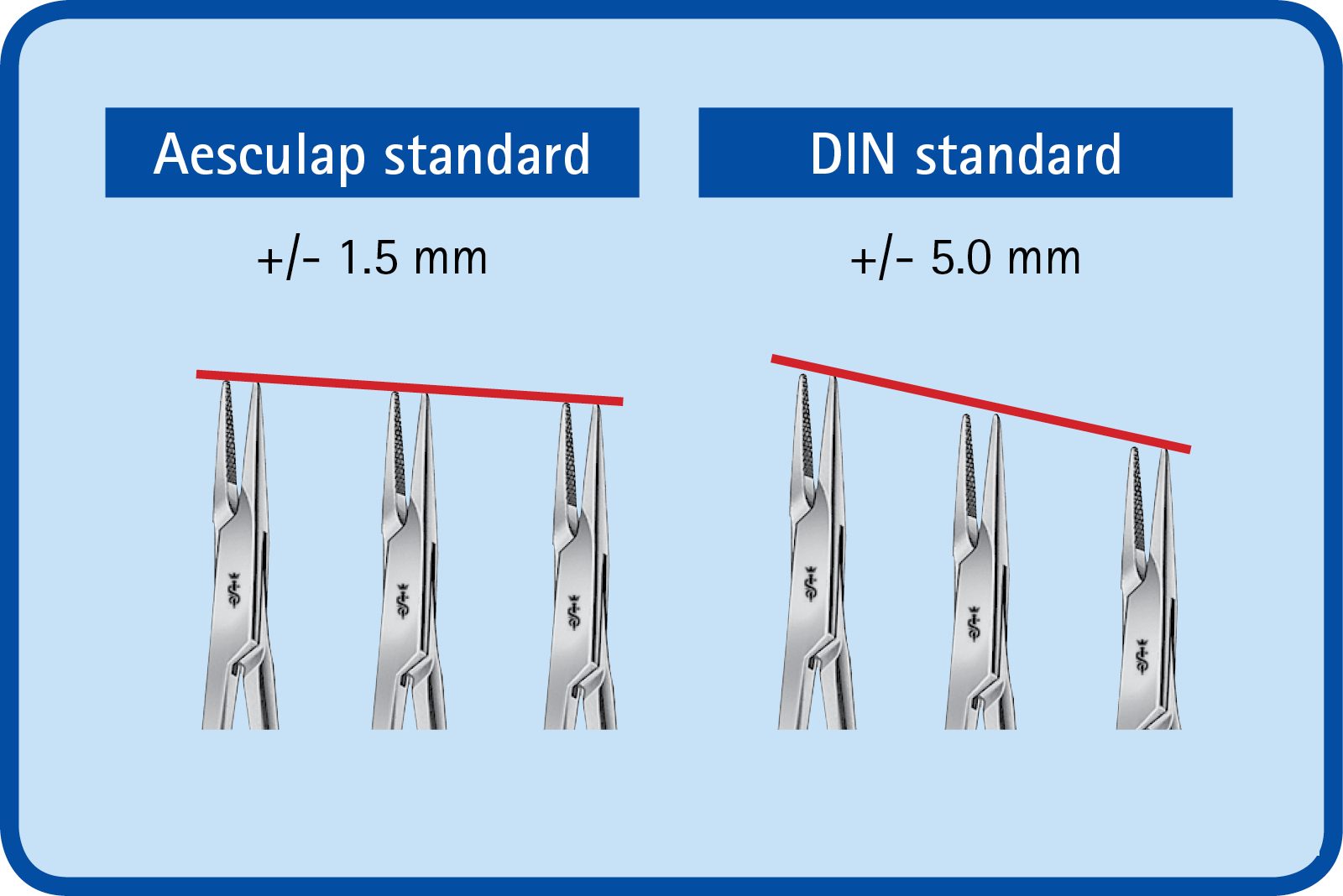

While all surgical instrument providers adhere to the national and international standards of DIN and ISO, Aesculap takes it one step further. Aesculap has self-imposed tighter regulations on its instrumentation to ensure that anything that leaves the manufacturing facility meets the highest standards.

Performance Quality

Performance Quality is a surgical instrument with a solid feel that performs like an extension of the surgeon’s own hand, with precision and reliability from the first use and throughout its lifetime. During the manufacturing of a surgical instrument, there may be as many as 15 steps. While most instrument providers outsource many of these steps to cut costs, Aesculap manufactures all of our surgical instruments in an Aesculap owned and operated plant, allowing us to control every aspect of the process. Our master craftsmen assure the consistency and reliability of our surgical instruments, delivering performance quality worthy of the Aesculap name.

Value

Aesculap produces quality instruments that are cost effective. But our support goes beyond the instrument alone.

Many facilities have instrument fleets worth millions of dollars. Even though surgical tools are a large asset for a facility, proper care and maintenance of these instruments is often overlooked. Failing to protect your instrument fleet can have serious ramifications for your overall hospital performance.

A study performed by the American College of Surgeons found that 5.9% of trays delivered to the OR contain broken instruments.* In a facility that delivers 1,000 trays to the OR a day, that’s 59 trays being used in surgery that contain broken instruments – increasing the possibility of adverse patient outcomes.

Aesculap provides solutions to help you avoid these issues and protect your investment.

Providing Solutions

Protect

With more than 10 FDA clearances for sterile containers, Aesculap can meet all of your container needs. Standardizing your containers can reduce product and process variability. Learn more >

Preserve

Did you know that 87% of instrument damage stems from issues with water?* Aesculap Technical Services can help you identify the source of wear and tear on your instruments and repair and refurbish them back to their original fit, form and function. Learn more >

Manage

Aesculap Surgical Asset Management Experts can help you streamline your instrument fleet. Our process eliminates unnecessary instruments from surgical sets, reducing inventories by an average of 17%.* Learn More >

Education

From earning credit hours online to conducting customized training courses in your facility, Aesculap Academy can support you and your staff with all of your education needs. Learn more >

Surgical Instruments

*Data on file